Rig Manager

Bit cut through shale and sand fine. No big damage. We finished the hole faster than usual and didn’t change tools.

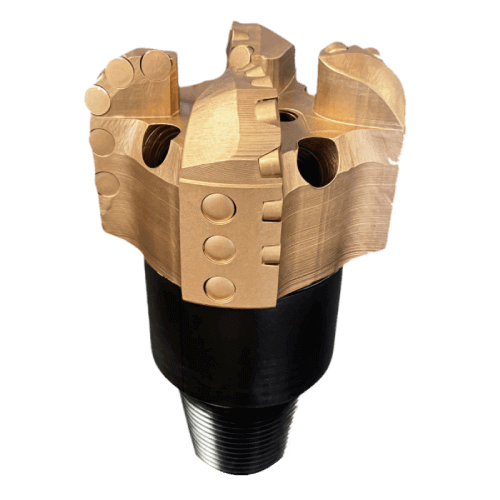

We offer a full range of PDC Bits, including matrix-body and steel-body designs, as well as customized options — all engineered to deliver efficient drilling across various rock formations.

We provide a comprehensive selection of PDC Bits, including matrix-body and steel-body options, as well as custom designs — all engineered to deliver reliable performance across various formations and drilling requirements.

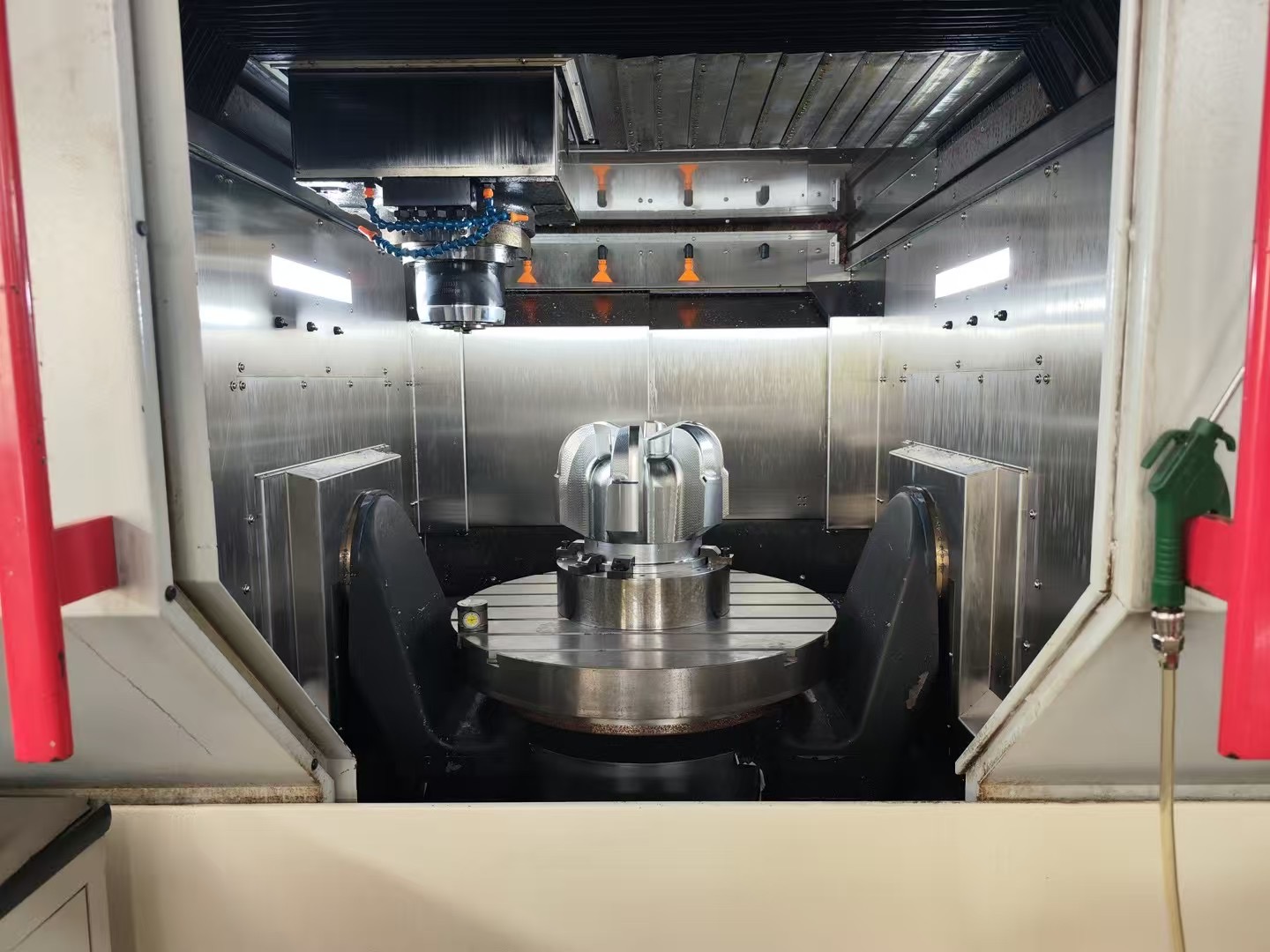

Through advanced manufacturing techniques, precision engineering, rigorous quality assurance, comprehensive durability testing, and innovative design, we craft PDC bits that set the standard for performance and reliability in the drilling industry.

At our facility, we employ advanced sintering techniques, precision machining, and rigorous quality assurance processes to manufacture high-performance PDC bits, ensuring durability and efficiency in diverse drilling applications.

Real customer reviews showing our products’ great performance in various projects.

Have questions? We’re here to help! Below are some of the most common questions about our PDC bits. If you don’t find your answer here, feel free to contact us anytime.

PDC bits use synthetic diamond cutters bonded to a tough steel body for high wear resistance.

PDC bits are ideal for soft to medium-hard formations and high drilling speed requirements.

Each bit goes through strict inspection and testing before shipment to guarantee durability and performance.